Express Production

Overview

The Express Production functionality streamlines the Issue and Receipt task in processing production.

Summary

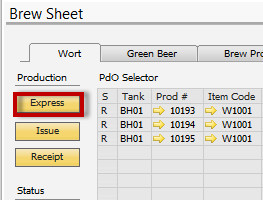

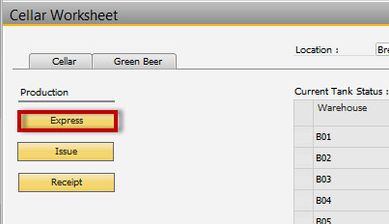

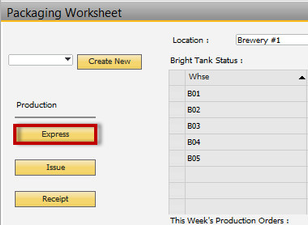

The Express screen is used on the Brew Sheet, Cellar Worksheet, and Packaging Worksheet. It conducts the Issue, Receipt and batch selection processes of production all in one screen.

Details

When processing production via the Express Screen you select the production order you want to process whether it is on the Brew, Cellar or Packaging sheet and then click the Express button.

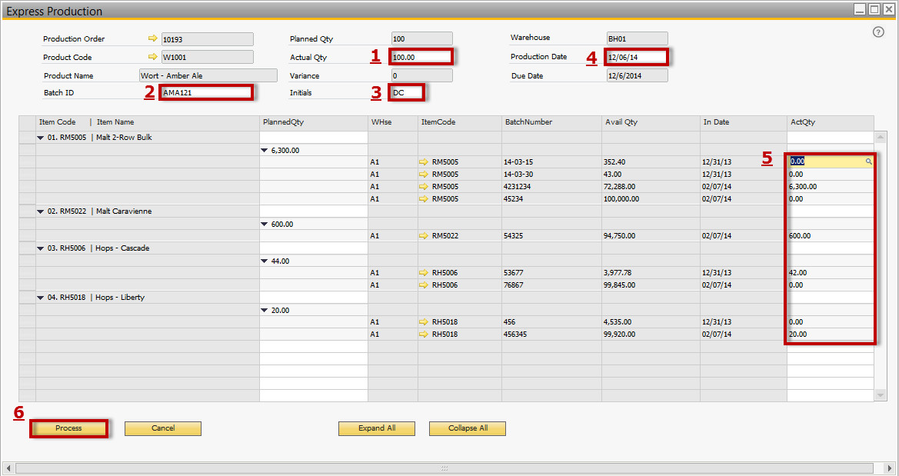

The following example will be based off of a Wort Production Order but the functionality is the same for any production process.

- Enter the actual quantity of the product that was produced. (Wort = Amount the recipe makes, GB = knockout amount received in the fermenter, BB = amount received into the bright tank)

- If the Batch was not pre-assigned then you will need to define that manually here.

- Place for the inputter to initial (not mandatory)

- Date the item was produced. This will default to the production date assigned on the production order.

- Select the batch of the material consumed and input the actual quantity consumed. NOTE: as a shortcut you can use the magnifying glass to pull in the Planned Quantity to that field.

- Once you have completely filled out the Express Screen click the Process button to finalize the process of this production order.

When the Express Production screen closes after processing you have successfully issued and received your production order. Next step will be to close it!